3.4 Regular Servicing

This servicing section started to end up monsterous, so I have moved it to a seperate page. I will add details here, and probably short videos. The primary source of information here is the ADF G609 Unimog Servicing Instruction, however I found that you need to look at several documents, and then check Facebook. The ADF used NATO or Military stock numbers and references for inter-operability and Integrated Logistic Support reasons, but these reasons dont apply to the now civilian-ised trucks. I have tried to keep the original details, but add civilian equivalent products and practices.

3.4.1 Servicing Sequence

The following servicing sequence is to be applied:

- Technical Inspection (TI) – 5 000 km or 12 months after the last service (this TI is to include a brake and clutch fluid change);

- Minor Service – 5 000 km or 12 months after the last TI;

- TI – 5 000 km or 12 months after the last Minor Service;

- Major Service – 5 000 km or 12 months after the last TI;

- TI – 5 000 km or 12 months after the last Major Service;

- Minor Service – 5 000 km or 12 months after the last TI;

- TI – 5 000 km or 12 months after the last Minor Service; and

- Alternate Major Service – 5 000 km or 12 months after the last TI.

I found the above statement confusing. This might help:

0km --- 5,000km Tech Inspect --- 10,000 Minor Service --- 15,0000 Tech Inspect --- 20,000 Major Service (repeat ... but) 40,000

- Alternate

| Serial | Item or Assembly | Technical Inspection (TI) | Minor Service | Major Service | Alternate Major Service | Capacity (litres) | Lubricant See notes on Lubricants |

Comments |

|---|---|---|---|---|---|---|---|---|

| First Parade Servicing | ||||||||

| FP1 | Check Engine oil & top up as necessary | - | - | - | - | 15 | SAE GRADE 40, (OMD-115), Castrol RX Super 15W-40 CJ-4/E9 | First Parade (i.e. daily) servicing |

| FP2 | Check Coolant Level & top up as necessary | - | - | - | - | - | PGXL (Cummins or Penrite) | First Parade (i.e. daily) servicing |

| FP3 | Check Windscreen Washer Level & top up as necessary | - | - | - | - | - | Water + Bar's Bugs | First Parade (i.e. daily) servicing |

| FP4 | Check Fuel Level & top up as necessary | - | - | - | - | - | Diesel | First Parade (i.e. daily) servicing |

| FP5 | Security. Check Spare Wheel is securely mounted. | - | - | - | - | - | First Parade (i.e. daily) servicing |

|

| FP6 | Truck Servicablity. Inspect the truck for any damage, and loose or missing parts. | - | - | - | - | - | First Parade (i.e. daily) servicing |

|

| FP7 | Tyres. Check tyre pressures and inspect treads and sidewalls. | - | - | - | - | - | First Parade (i.e. daily) servicing |

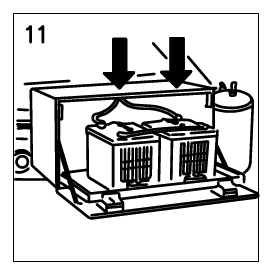

|

| FP8 | Leakage. Check under trucks for signs of coolant, oil or fuel leakage. | - | - | - | - | - | First Parade (i.e. daily) servicing |

|

| FP9 | Crane (if fitted), check that it is stowed, check oil level, and check hoses. | - | - | - | - | - | First Parade (i.e. daily) servicing |

|

| FP10 | Dump (if fitted),check Oil and top up if necessary, check all hoses. | - | - | - | - | - | First Parade (i.e. daily) servicing |

|

| FP11 | Air Pressure Check. Start the engine and check that pressure rises above 12bar and light extinguish. | - | - | - | - | - | First Parade (i.e. daily) servicing |

|

| FP12 | Accessories. Check horn, headlights, stop lights, indicators, hazard lights, windsreen washers & wipers work. | - | - | - | - | - | First Parade (i.e. daily) servicing |

|

| FP13 | Brakes. Allow the truck to move forward slightly and check that the foot brake works. | - | - | - | - | - | First Parade (i.e. daily) servicing |

|

| FP14 | Steering. Whilst moving slowly, check that the steering is free and responsive. | - | - | - | - | - | First Parade (i.e. daily) servicing |

|

| FP15 | General. Check all lashings and tie downs. | - | - | - | - | - | First Parade (i.e. daily) servicing |

|

| Halt Parade Servicing | ||||||||

| HP1 | Engine. Check engine oil and top up as necessary. | - | - | - | - | - | Halt Parade (i.e. after 4 hours, or when stopped for a break) servicing

|

|

| HP2 | Radiator. Check coolant level and top up as required. | - | - | - | - | - | Halt Parade (i.e. after 4 hours, or when stopped for a break) servicing

|

|

| HP3 | Fuel. Check fuel level and top up / refuel as required. | - | - | - | - | - | Halt Parade (i.e. after 4 hours, or when stopped for a break) servicing |

|

| HP4 | Tyres. Check tyre pressures and inspect treads and sidewalls. | - | - | - | - | - | Halt Parade (i.e. after 4 hours, or when stopped for a break) servicing see Unimog Notes Tyre Pressures |

|

| Last Parade Servicing | ||||||||

| LP1 | Fuel. Fill the fuel tank. | - | - | - | - | - | Last Parade (i.e. at end of day or end of trip) servicing |

|

| LP2 | Engine. Check oil level and top up as necessary. | - | - | - | - | - | Last Parade (i.e. at end of day or end of trip) servicing

|

|

| LP3 | Radiator. Check the coolant level and top up as necessary. | - | - | - | - | - | Last Parade (i.e. at end of day or end of trip) servicing

|

|

| LP4 | Parking. Ensure the truck is parked correctly, out of gear, forward-reverse out of gear, park brake on. | - | - | - | - | - | Last Parade (i.e. at end of day or end of trip) servicing |

|

| LP5 | Crane (if fitted). Controls at neutral and crane and stabalisers stowed. | - | - | - | - | - | Last Parade (i.e. at end of day or end of trip) servicing |

|

| LP6 | General. Ensure truck is clean. | - | - | - | - | - | Last Parade (i.e. at end of day or end of trip) servicing |

|

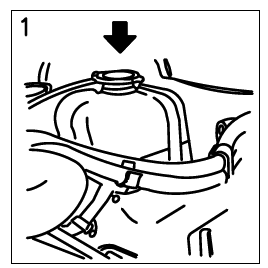

| 1 | Engine oil | - | Drain & Refill | Drain & Refill | Drain & Refill | 15 | SAE GRADE 40, (OMD-115), Castrol RX Super 15W-40 CJ-4/E9 |   |

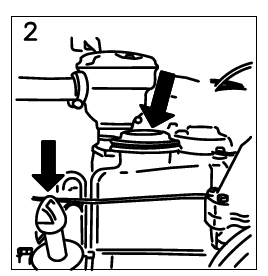

| 2 | Engine oil filter | - | Replace | Replace | Replace |  |

||

| 3 | Transmission oil | - | Top Up | Drain & Refill | Drain & Refill | 10.5 | SAE GRADE 40, (OMD-115), Castrol RX Super 15W-40 CJ-4/E9 |    |

| 4 | PTO transmission oil | - | Top Up | Drain & Refill | Drain & Refill | 5.75 | SAE GRADE 40, (OMD-115), Castrol RX Super 15W-40 CJ-4/E9 | For Mogs with PTO Winches |

| 5 | Front and rear differential oils | - | Top Up | Drain & Refill | Drain & Refill | 2.5 | OEP-220, CASTROL AXLE AP 85W-140, Gear oil SAE 90 |

|

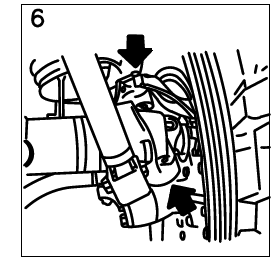

| 6 | Front and rear reduction hub oils | - | Top Up | Drain & Refill | Drain & Refill | 0.6 | OEP-220, CASTROL AXLE AP 85W-140, Gear oil SAE 90 |

|

| 7 | Park brake lever | - | Lubricate | Lubricate | Lubricate | XG-291, Castrol Lithium Grease High Temperature | ||

| 8 | Power steering reservoir | - | Top Up | Top Up | Drain & Refill | 2.25 | OX-47, CASTROL AGRI TRANS PLUS 80W |  |

| 9 | Steering system | - | Lubricate | Lubricate | Lubricate | XG-291, Castrol Lithium Grease High Temperature |  |

|

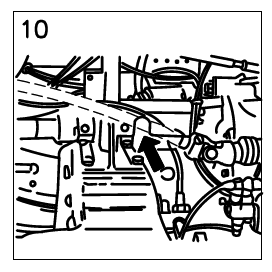

| 10 | Clutch to transmission drive shaft | - | Lubricate | Lubricate | Lubricate | XG-291, Castrol Lithium Grease High Temperature | ||

| 11 | PTO transmission shaft joints | - | Lubricate | Lubricate | Lubricate | XG-291, Castrol Lithium Grease High Temperature | For Mogs with PTO Winches |

|

| 12 | PTO winch driveshaft | - | Lubricate | Lubricate | Lubricate | XG-291 | For Mogs with PTO Winches | |

| 13 | Winch dog clutch shaft | - | Lubricate | Lubricate | Lubricate | Molybond 122L (NSN 9150- 66-089-5365) | For Mogs with PTO Winches | |

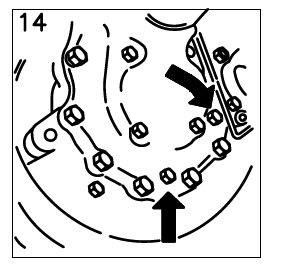

| 14 | Winch mounting pins | - | Lubricate | Lubricate | Lubricate | Molybond 122L (NSN 9150- 66-089-5365) | For Mogs with PTO Winches | |

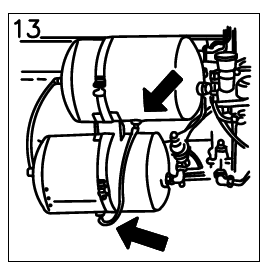

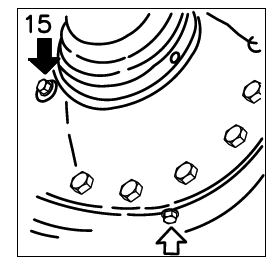

| 15 | Winch oil | - | Top Up | Drain & Refill | Drain & Refill | 2.0 | OEP-220, CASTROL AXLE AP 85W-140, Gear oil SAE 90 |

|

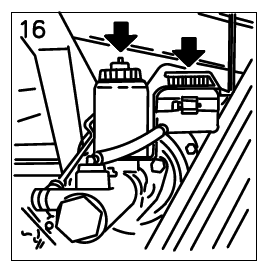

| 16 | Winch fairleads and rollers | - | Lubricate | Lubricate | Lubricate | XG-291, Castrol Lithium Grease High Temperature | ||

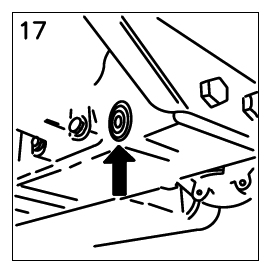

| 17 | Winch rope | - | Clean & Lubricate | Clean & Lubricate | Clean & Lubricate | XG-291, Castrol Lithium Grease High Temperature | ||

| 18 | Engine brake linkage | - | Lubricate | Lubricate | Lubricate | XG-291, Castrol Lithium Grease High Temperature |  |

|

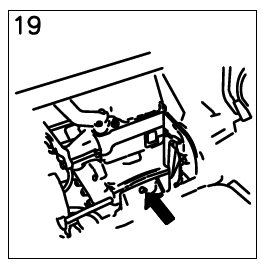

| 19 | Door locks and hinges | - | Lubricate | Lubricate | Lubricate | XG-291, Castrol Lithium Grease High Temperature | ||

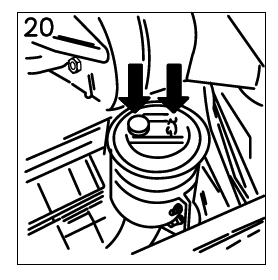

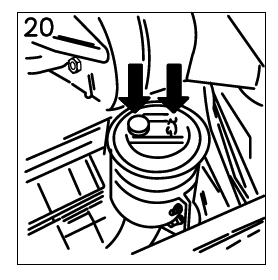

| 20 | Fuel tank | - | Drain & Refill (Check for Water) | Drain & Refill (Check for Water) | Drain & Refill (Check for Water) | |||

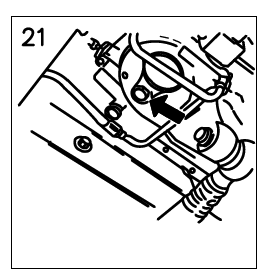

| 21 | Fuel pre-filter | - | Clean | Clean | Clean |  |

||

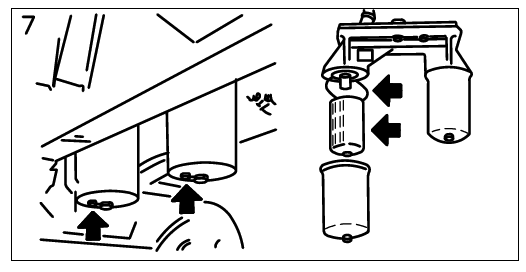

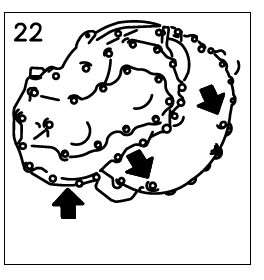

| 22 | Main Fuel filters | - | - | Replace | Replace |  |

||

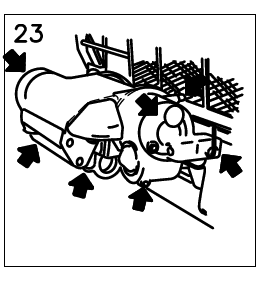

| 23 | Air filter | - | Clean | Clean | Clean |  |

||

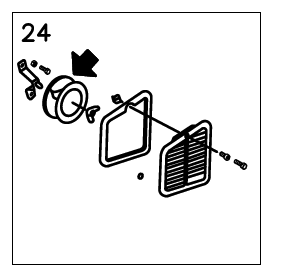

| 24 | Spare wheel carrier operation | - | Inspect | Inspect | Inspect | |||

| 25 | Bonnet locks and hinges | - | Lubricate | Lubricate | Lubricate | SAE GRADE 40 (OMD-115) | ||

| 26 | Accelerator cross shaft and pedal pivot | - | Clean & Lubricate | Clean & Lubricate | Clean & Lubricate | XG-291, Castrol Lithium Grease High Temperature | ||

| 27 | Tailgate hinges, catches - and latches | - | Lubricate | Lubricate | Lubricate | SAE GRADE 40, (OMD-115), Castrol RX Super 15W-40 CJ-4/E9 | ||

| 28 | Battery compartment - slides | - | Lubricate | Lubricate | Lubricate | XG-291, Castrol Lithium Grease High Temperature |  |

|

| 29 | Battery electrolyte level (bottom of the filler spouts), security and cleanliness of terminals and posts | - | Top Up & Clean | Top Up & Clean | Top Up & Clean | Spray battery Terminal posts with CRC Battery Terminal Protector. | ||

| 30 | Seat slides | - | Lubricate | Lubricate | Lubricate | XG-291, Castrol Lithium Grease High Temperature | ||

| 31 | Driving mirrors and window glasses | - | Clean & Inspect | Clean & Inspect | Clean & Inspect | XG-291, Castrol Lithium Grease High Temperature | ||

| 32 | Tyre pressures | - | Inspect | Inspect | Inspect | See Tyre Pressures section. | ||

| 33 | Wheel nut security | - | Inspect | Inspect | Inspect | |||

| 34 | Spare wheel security | - | - | Inspect | Inspect | |||

| 35 | Spare wheel winch operation | - | Inspect | Inspect | Inspect | |||

| 36 | Pintle Hook | - | Lubricate | Lubricate | Lubricate | XG-291, Castrol Lithium Grease High Temperature | ||

| 37 | Tray twist locks | - | Lubricate | Lubricate | Lubricate | SAE GRADE 40, (OMD-115), Castrol RX Super 15W-40 CJ-4/E9 | If fitted. | |

| 38 | CES | - | Inspect | Inspect | Inspect | Need to find out what CES stands for. | ||

| 39 | Vehicle jack classification tag | - | Inspect | Inspect | Inspect | |||

| 40 | Vehicle fire extinguisher inspection tag | - | Inspect | Inspect | Inspect | |||

| 40 | Vehicle cleanliness | - | Clean | Clean | Clean | |||

| 42 | Hydraulic oil reservoir | - | Top Up | Drain & Refill | Drain & Refill | OM-33, Castrol OM-33 | Dump Truck only | |

| 43 | Hydraulic oil filter | - | - | Replace | Replace | Dump Truck only | ||

| 44 | Hoist cylinder and tailgate trunnions | - | Lubricate | Lubricate | Lubricate | XG-291, Castrol Lithium Grease High Temperature | Dump Truck only | |

| 45 | Tailgate cylinder | - | - | Clean & Lubricate | Clean & Lubricate | XG-291, Castrol Lithium Grease High Temperature | Dump Truck only | |

| 46 | Tailgate hinge lever | - | Clean | Clean | Clean | XG-291, Castrol Lithium Grease High Temperature | Dump Truck only | |

| 47 | Dump system operation incl. locks and gauges | - | Action Required | Action Required | Action Required | Dump Truck only | ||

| 48 | Engine mounting bolts | - | - | Inspect | Inspect | Tradesperson Task. Inspect the engine mounting bolts for the correct tension in accordance with EMEI Vehicle G 603. | ||

| 49 | Exhaust manifold bolts security | - | - | Inspect | Inspect | Tradesperson Task | ||

| 50 | Valve clearance | - | - | Inspect | Inspect | Tradesperson Task | ||

| 51 | Engine breather filter | - | - | - | Replace | Tradesperson Task | ||

| 52 | Front and rear axle stabiliser bar mounting bolts security (bracket to chassis) | - | Inspect | Inspect | Inspect | Tradesperson Task | ||

| 53 | Front and rear strut - securing bolts security (axle to torque tube) | - | - | Inspect | Inspect | Tradesperson Task | ||

| 54 | Front and rear pan hard rod securing bolts security (axle to chassis) | - | Inspect | Inspect | Inspect | Tradesperson Task. The panhard rod securing bolt is not to be over-tightened. If the bolt is over-tightened, the bush inner sleeve may collapse. Tighten the bolt to 315 N.m. | ||

| 55 | Transmission mounting - bolts security | - | - | Inspect | Inspect | Tradesperson Task | ||

| 56 | Transmission shift - mechanism | - | - | Inspect | Inspect | Tradesperson Task. Confirm the transmission shift mechanism operates correctly and that the expansion plug is present and secure in accordance with EMEI Vehicle G 617-29. | ||

| 57 | Power steering reservoir | - | - | Inspect | Inspect | OX-47, CASTROL AGRI TRANS PLUS 80W | Tradesperson Task |

|

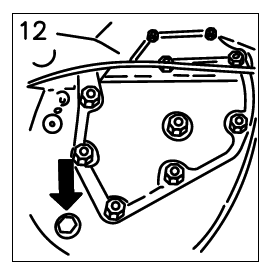

| 58 | Power steering oil filter | - | - | - | Replace | Tradesperson Task |

||

| 59 | Steering system | - | Inspect | Inspect | Inspect | Tradesperson Task | ||

| 60 | Steering box mounting bolts security | - | - | Inspect | Inspect | Tradesperson Task | ||

| 61 | Compressed air system - including pipes and hoses | - | Inspect | Inspect | Inspect | Tradesperson Task | ||

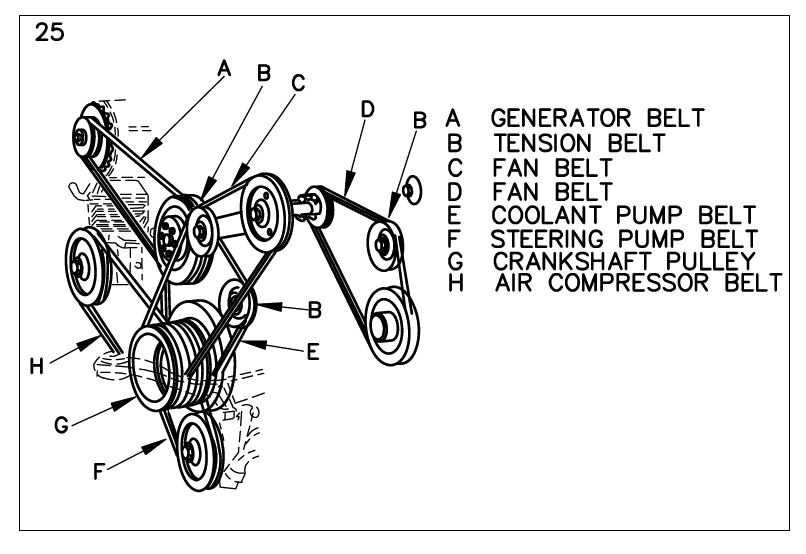

| 62 | Drive belts | - | Inspect | Inspect | Inspect | Tradesperson Task |

||

| 63 | Fuel lines for chaffing, - leaks and security | - | Inspect | Inspect | Inspect | Tradesperson Task | ||

| 64 | Air filter | - | Inspect | Inspect | Inspect | Tradesperson Task. Clean the air filter in accordance with EMEI Vehicle A 591-1. |

||

| 65 | Air system operation | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 66 | Brake hydraulic system | Drain & Refill, then Bleed | Drain & Refill, then Bleed | Drain & Refill, then Bleed | Drain & Refill, then Bleed | 1.0 | OX-8, CASTROL AGRI TRANS PLUS 80W | OX-8 is a rust inhibiting hydraulic fluid. Tradesperson Task. |

| 67 | Brake system operation | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 68 | Brake pad wear | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 69 | Clutch hydraulic system | Drain & Refill, then Bleed | Drain & Refill, then Bleed | Drain & Refill, then Bleed | Drain & Refill, then Bleed | 0.2 | OX-8, CASTROL AGRI TRANS PLUS 80W | OX-8 is a rust inhibiting hydraulic fluid. Tradesperson Task. |

| 70 | Clutch system operation | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 71 | Tray to chassis mounting bolts security | - | - | Inspect | Inspect | Tradesperson Task. | ||

| 72 | Cab to chassis mounting bolts security | - | - | Inspect | Inspect | Tradesperson Task. | ||

| 73 | Engine brake operation | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 74 | Generator mounting bolts security | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 75 | Brake caliper shroud securing bolts security | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 76 | Fuel pre-filter | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 77 | Accelerator linkage and pedal stop bolt | - | - | Inspect | Inspect | Tradesperson Task. Remove the accelerator cross shaft cover. Clean and lubricate the shaft. Inspect the accelerator pedal for the presence of an accelerator stop bolt. If the stop bolt is not fitted, modify the accelerator pedal in accordance with EMEI Vehicle G 617-4. If required, set the throttle linkage in accordance with EMEI Vehicle G 603 (adjust as required). | ||

| 78 | Radiator coolant | - | Inspect | Drain & Refill | Drain & Refill | Tradesperson Task. Inspect and pressure test the cooling system in accordance with EMEI Vehicle G 603.  |

||

| 79 | Suspension components | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 80 | Drive shafts and universal joints | - | Inspect | Inspect | Inspect | Tradesperson Task. |

||

| 81 | Cabin heating and ventilation system filter | - | Inspect | Inspect | Inspect | Tradesperson Task. Clean the air filter in accordance with EMEI Vehicle A 591-1.  |

||

| 82 | Spare wheel winch and cable | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 83 | PTO driveshaft | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 84 | Winch dog clutch operation | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 85 | Winch mounting pins | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 86 | Winch operation | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 87 | Winch rope and CES recovery items | - | Inspect | Inspect | Inspect | Tradesperson Task. The winch rope is to be cleaned using mains pressure fresh water. The winch rope is not to be cleaned using high pressure cleaners. Once cleaned, the winch rope is to be inspected in accordance with EMEI Vehicle D 108 prior to lubricating. A winch rope that is fully functional can be wound back onto the winch drum. The recovery items, e.g. chain, shackles etc that are part of the vehicle CES are to be inspected in accordance with EMEI Vehicle D 108. Inspection of the winch rope and recovery CES items is a part of this check/service and must be completed if the vehicle is to be classified ‘Fully Functional’. | ||

| 88 | Winch torque limiter | - | - | Inspect | Inspect | Tradesperson Task. Calibrate the winch torque limiter in accordance with EMEI Vehicle G 619-29. | ||

| 89 | Tyres | - | Inspect | Inspect | Inspect | Tradesperson Task. Inspect the tyres in accordance with EMEI Vehicle A 298-2. | ||

| 90 | Wheel alignment | - | Inspect | Inspect | Inspect | Tradesperson Task. Carry out a wheel alignment in accordance with EMEI Vehicle G 603. | ||

| 91 | Body/chassis condition | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 92 | Seat belts, mountings and inertia reel operation | - | Inspect | Inspect | Inspect | Tradesperson Task. Inspect the seat belts in accordance with EMEI Vehicle A 548-1. | ||

| 93 | Headlight alignment | - | Inspect | Inspect | Inspect | Tradesperson Task. Carry out the head light alignment in accordance with EMEI Vehicle G 603. | ||

| 94 | Operation of lights, gauges, warning lights and horn | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 95 | Tailgate/sidegate hinges and hinge mounts | - | Inspect | Inspect | Inspect | Tradesperson Task. Inspect all tail/sidegate hinge pins and mounts for signs of damage, deformation and cracking. Check the hinge pin and hinge gap in accordance with EMEI Vehicle G 609-7. | ||

| 96 | Safety chain mounts secure and complete | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 97 | Pintle hook | - | Inspect | Inspect | Inspect | Tradesperson Task. Inspect the pintle hook in accordance with EMEI Vehicle A 049-1. | ||

| 98 | NATO plug operation | - | Inspect | Inspect | Inspect | Tradesperson Task. | ||

| 99 | Vehicle jack | - | Inspect | Inspect | Inspect | Tradesperson Task. Inspect the vehicle jack in accordance with EMEI Workshop H 149-1. | ||

| 100 | Hydraulic oil pump and mounting bracket | - | Inspect | Inspect | Inspect | Tradesperson Task. Dump Truck Only. | ||

| 101 | Hydraulic oil pump drive | - | Inspect | Inspect | Inspect | Tradesperson Task. Dump Truck Only. | ||

| 102 | Tailgate locking switch | - | Inspect | Inspect | Inspect | Tradesperson Task. Dump Truck Only. | ||

| 103 | Dump system operation incl. locks and gauges | - | Inspect | Inspect | Inspect | Tradesperson Task. Dump Truck Only. | ||

| 104 | Airlines, hoses, bushes and clamps | - | Inspect | Inspect | Inspect | Tradesperson Task. Dump Truck Only. | ||

| 105 | Hoist cylinder mounting - bolts | - | Inspect | Inspect | Inspect | Tradesperson Task. Dump Truck Only. | ||

| 106 | Hoist valve connections | - | Inspect | Inspect | Inspect | Tradesperson Task. Dump Truck Only. | ||

| 107 | Tailgate cylinder | - | Inspect | Inspect | Inspect | Tradesperson Task. Dump Truck Only. | ||

| 108 | Tailgate hinge lever | - | Inspect | Inspect | Inspect | Tradesperson Task. Dump Truck Only. | ||

| 109 | Hoist valve mounting bolts | - | Inspect | Inspect | Inspect | Tradesperson Task. Dump Truck Only. | ||

| 110 | Chassis sub-frame mounting bolts | - | Inspect | Inspect | Inspect | Tradesperson Task. Dump Truck Only. | ||

| 111 | Dumpbody | - | Inspect | Inspect | Inspect | Tradesperson Task. Dump Truck Only. | ||

| 112 | Crane useability | Inspect | Inspect | Inspect | Inspect | Tradesperson Task. Cargo with Crane Only. The crane is to be inspected for useability in accordance with EMEI Vehicle A 028-1 and serviced in accordance with EMEI Vehicle G 629. | ||

| 113 | Road test | Action Required | Action Required | Action Required | Action Required | Tradesperson Task. All variants. Road test the vehicle in accordance with EMEI Vehicle A 029-2. | ||

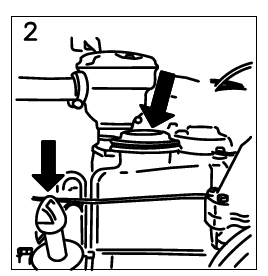

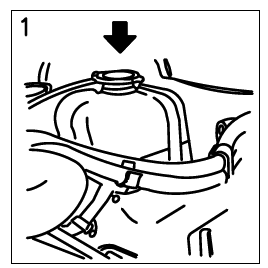

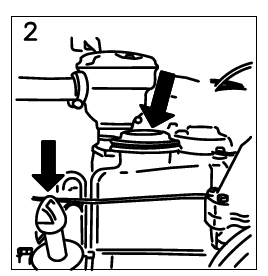

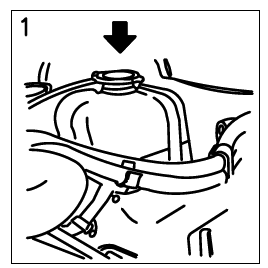

3.4.1 Check Engine Oil

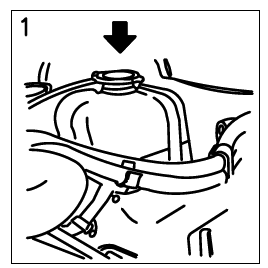

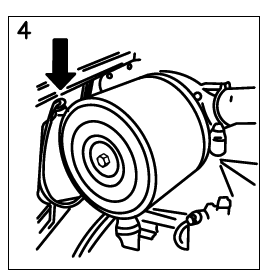

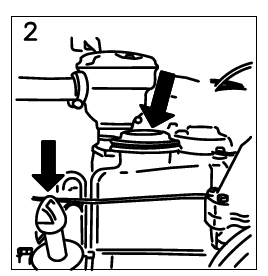

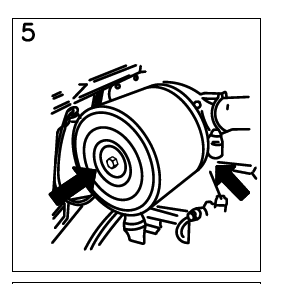

3.4.2 Greasing

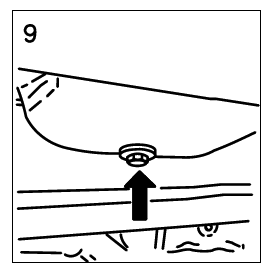

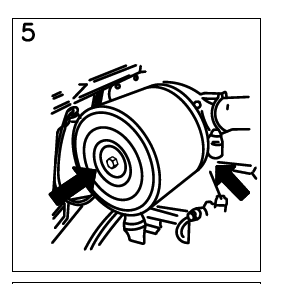

The Unimog is old school, and it requires greasing of many points. A few users on Facebook report that this is not as simple as it sounds. One user reported that they purchased a Makita grease gun kit, only to find that "it does not clip onto the nipple properly and none of the grease actually got into where it needs to go." Several users indicated the need for quick release coupler and flexible high pressure whip hose. The amount of grease points / volume of grease makes little 'hand grease pumps' fairly hard work. Most owners appear to have gone for a battery powered grease gun.